Ha ho bapisoa le tšepe, lisebelisoa tse kopantsoeng tsa fiber tse matlafalitsoeng li na le thepa e bobebe le boima bo ka tlase ho karolo ea boraro ea tšepe.Leha ho le joalo, mabapi le matla, ha khatello ea kelello e fihla ho 400MPa, litšepe tsa tšepe li tla ba le khatello ea maikutlo, ha matla a matla a lisebelisoa tsa khalase a ka fihla ho 1000-2500MPa.Ha ho bapisoa le lisebelisoa tsa tšepe tse tloaelehileng, lisebelisoa tsa khalase tsa fiber li na le sebopeho se sa tšoaneng le anisotropy e hlakileng, e nang le mekhoa e mengata ea ho hlōleha.Lipatlisiso tsa liteko le tsa khopolo-taba tlas'a mefuta e fapaneng ea meroalo li ka fana ka kutloisiso e pharaletseng ea thepa ea bona ea mechine, haholo-holo ha e sebelisoa masimong a kang thepa ea tšireletso ea naha le sefofane, e hlokang lipatlisiso tse tebileng ka litšobotsi tsa bona le thepa ea mochine ho finyella litlhoko tsa bona tikoloho ya tshebediso.

Lintlha tse latelang li kenyelletsa thepa ea mechine le tlhahlobo ea tšenyo ea ka morao ea lisebelisoa tsa khalase ea fiber, ho fana ka tataiso bakeng sa tšebeliso ea thepa ena.

(1) Thepa ea tensile le tlhahlobo:

Patlisiso e bonts'itse hore thepa ea mochini oa fiber ea khalase e matlafalitsoeng ke lisebelisoa tse kopaneng tsa epoxy resin e bonts'a hore matla a ho tiea ka lehlakoreng le ts'oanang la thepa a maholo ho feta a lehlakoreng le otlolohileng la fiber.Ka hona, ka ts'ebeliso e sebetsang, tataiso ea fiber ea khalase e lokela ho bolokoa ka mokhoa o ts'oanang ka hohle kamoo ho ka khonehang le tataiso e tsitsitseng, e sebelise ka botlalo thepa ea eona e babatsehang ea ho tsitsisa.Ha ho bapisoa le tšepe, matla a ho tiea a phahame haholo, empa boima bo tlase haholo ho feta ba tšepe.Ho ka bonoa hore, Thepa e felletseng ea mochini oa lisebelisoa tse kopaneng tsa fiber ea khalase e batla e phahame.

Patlisiso e bonts'itse hore ho eketsa bongata ba fiber ea khalase e kentsoeng lisebelisoa tsa motsoako oa thermoplastic butle-butle ho eketsa matla a ho tiea a thepa e kopaneng.Lebaka le ka sehloohong ke hore ha likhalase tsa fiber li ntse li eketseha, likhoele tse ngata tsa khalase tse entsoeng ka motsoako li tlas'a matla a ka ntle.Ka nako e ts'oanang, ka lebaka la keketseho ea palo ea likhoele tsa khalase, matrix a resin lipakeng tsa likhoele tsa khalase e ba mosesaane, e leng se loketseng ho aha liforeimi tse matlafalitsoeng tsa fiber ea khalase.Ka hona, Keketseho ea likhalase tsa fiber ea khalase e baka khatello ea maikutlo e eketsehileng ho tloha ho resin ho ea ho fiber ea khalase ka thepa e kopantsoeng tlas'a meroalo e ka ntle, ka katleho ho ntlafatsa thepa ea bona ea ho tsitsisa.

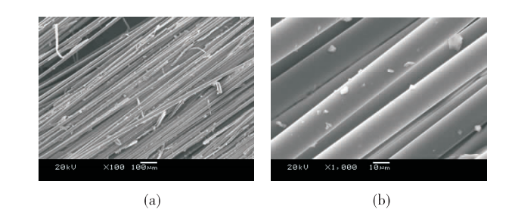

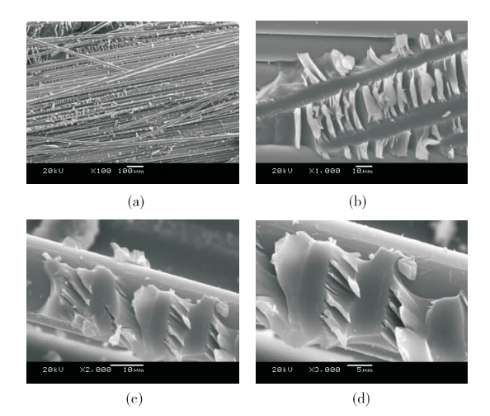

Patlisiso mabapi le liteko tse thata tsa khalase ea fiber unsaturated polyester composite e bonts'itse hore mokhoa oa ho hloleha oa lisebelisoa tsa khalase tse matlafalitsoeng ke ho hloleha ho kopaneng ha likhoele le matrix a resin ka ho lekola microscope ea elektrone ea karolo ea tensile.Sebaka se robehileng se bontša hore palo e kholo ea likhoele tsa khalase e ntšoa ka har'a matrix ea resin e karolong e tsitsitseng, 'me bokaholimo ba likhoele tse ntšoang ho matrix a resin bo boreleli ebile bo hloekile, bo na le likhechana tse fokolang tsa resin tse khomarelang holimo. ea likhoele tsa khalase, Ts'ebetso ke ho robeha ha brittle.Ka ho ntlafatsa sehokelo sa khokahano lipakeng tsa likhoele tsa khalase le resin, bokhoni ba ho kenella ba tse peli bo ea ntlafatsoa.Karolong e tsitsitseng, boholo ba likhechana tsa matrix resin tse nang le likhoele tse ngata tsa khalase li ka bonoa.Tlhokomeliso e 'ngoe e bonts'a hore palo e kholo ea li-bond tsa matrix resin holim'a likhoele tse ntšitsoeng tsa khalase 'me e fana ka tlhophiso e kang kama.Sebaka sa fracture se bontša fracture ea ductile, e ka finyellang thepa e ntle ea mochine.

(2) Ts'ebetso ea ho kheloha le tlhahlobo:

Liteko tse tharo tsa mokhathala o kobehang li ile tsa etsoa lipoleiting tse sa laoleheng le 'mele ea ho lahla resin ea fiber ea khalase e matlafalitsoeng ke lisebelisoa tse kopaneng tsa epoxy resin.Liphello li bontšitse hore ho satalla ho kobeha ha bobeli ho ile ha tsoela pele ho fokotseha ka ho eketseha ha linako tsa mokhathala.Leha ho le joalo, ho satalla ho kobehang ha fiber ea khalase e matlafalitsoeng ka lipoleiti tsa unidirectional e ne e phahame haholo ho feta ea 'mele ea ho lahla,' me sekhahla sa ho fokotseha ha ho satalla ho kobeha se ne se lieha.Ho bile le linako tse ling tsa mokhathala oa mapetsong a hlahang ha nako e ntse e ea, ho bonts'a hore fiber ea khalase e na le phello e ntlafetseng ts'ebetsong ea ho kobeha ha matrix.

Ka kenyelletso ea likhoele tsa khalase le keketseho ea butle-butle ea karoloana ea molumo, matla a ho kobeha a lisebelisoa tse kopaneng le ona a eketseha ho latela.Ha karolo ea fiber volume e le 50%, matla a eona a ho kobeha a phahame ka ho fetisisa, e leng 21.3% e phahameng ho feta matla a pele.Leha ho le joalo, ha karoloana ea bophahamo ba fiber e le 80%, matla a kobehang a lisebelisoa tse kopantsoeng a bontša phokotseho e kholo, e tlase ho feta matla a sampole ntle le fiber.Ka kakaretso ho lumeloa hore, Matla a fokolang a thepa e ka 'na ea e-ba ka lebaka la li-microcracks tse ka hare le li-voids tse thibelang phetisetso e atlehang ea mojaro ka matrix ho likhoele,' me tlas'a matla a ka ntle, li-microcracks li atoloha ka potlako ho theha liphoso, qetellong li baka tšenyo. Khokahano e kopanyang ea khalase ena ea fiber e kopantsoeng haholo e itšetlehile ka phallo ea viscous ea khalase ea fiber matrix mochesong o phahameng ho phuthela likhoele, 'me likhoele tse feteletseng tsa khalase li sitisa haholo phallo ea matrix, e bakang tšenyo e itseng ho tsoelapele lipakeng tsa eona. li-interfaces.

(3) Ts'ebetso ea khanyetso ea ho kenella:

Tšebeliso ea lisebelisoa tse matla tsa khalase tse matlafalitsoeng bakeng sa sefahleho le mokokotlo oa lihlomo tsa karabelo li na le khanyetso e ntle ea ho kenella ha e bapisoa le tšepe ea alloy ea setso.Ha ho bapisoa le tšepe ea alloy, lisebelisoa tse kopaneng tsa khalase bakeng sa sefahleho le mokokotlo oa lihlomo tse phatlohang li na le likhechana tse nyane tse setseng kamora ho phatloha, ntle le matla a ho bolaea, 'me li ka felisa karolo ea bobeli ea phello ea polao ea lihlomo tse phatlohang.

Nako ea poso: Nov-07-2023